Vibration Analysis of Seismic Plinths in a Semiconductor Cleanroom

Independent vibration assessment confirmed compliance for precision tools on seismic plinths, revealed horizontal stiffness asymmetry linked to non-symmetrical plinth geometry, and defined an engineering pathway to improved plinth performance via FEA, modal analysis, and model updating.

The Challenge

A semiconductor industry leader required assurance that seismic plinths supporting vibration-sensitive tools (including an ASML PAS 5500 and a TEL8 unit) would maintain performance in a cleanroom where the floor construction deviated from the original specification.

Verify the ASML plinth against the manufacturer’s vibration criteria.

Benchmark the TEL8 plinth against the VC-D criterion (6.25 µm/s RMS).

Assess transient response using controlled heel-drop tests.

Our Approach

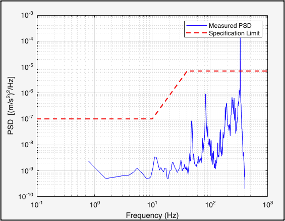

Calibrated accelerometers were mounted directly on each plinth to record ambient vibration in three orthogonal directions (X, Y, Z). Analysis included Power Spectral Density (PSD), 1/3-octave band centre frequencies, and partially integrated 1 Hz bandwidths. Heel-drop tests were used to characterise impulsive behaviour.

Continuity with earlier work (approved mounting positions, consistent instrumentation and processing).

Comparison to ASML documentation and VC-D reference, as appropriate.

Findings

ASML plinth: Ambient vibration was within manufacturer limits across all axes and evaluation formats.

TEL8 plinth: No published criterion; benchmarking versus VC-D showed acceptable levels.

Heel-drop tests: Vertical axis exceedances of VC-D (expected for impulsive excitation); horizontal axes remained below reference.

Stiffness asymmetry: The two horizontal directions were not equal — one axis showed consistently higher vibration, indicating lower stiffness in that horizontal plane. This behaviour is consistent with a non-symmetrical plinth design. Ideally, seismic plinths should exhibit uniform stiffness in all planes.

Outcome

Both plinths were suitable for precision operation under ambient conditions. Beyond compliance, the analysis provided actionable structural insights:

Transient sensitivity was evident in the vertical axis under heel-drop excitation.

Horizontal asymmetry pointed to a stiffness imbalance linked to non-symmetrical plinth geometry.

We can progress from measurement → diagnosis → design improvement, applying Finite Element Analysis (FEA), modal analysis, and model updating to develop and validate plinths with uniform stiffness and predictable vibration performance, and to demonstrate engineering compliance with manufacturer criteria and international standards.

Client Perspective

“A detailed and thorough report, giving us complete confidence in the vibration performance of our cleanroom equipment.”

— Sales Director, International Equipment Supplier

Lessons Learned

Independent testing can validate compliance even when floor construction deviates from specification.

Benchmarking against VC-D provides assurance where manufacturer criteria are absent.

Heel-drop tests reveal transient amplification and floor–plinth interaction behaviours.

Plinth symmetry and stiffness uniformity are critical to stable vibration performance.

Modal analysis & model updating align predicted behaviour with measured results and de-risk design changes.

Why This Matters

Semiconductor tools are extremely vibration-sensitive. Uncontrolled vibration risks misalignment, yield loss, and downtime. This case study shows how rigorous measurement paired with mechanical engineering (FEA, modal analysis, model updating) safeguards performance and provides a clear route to better plinth design where required.

Related Services

This project illustrates how our core services combine to resolve critical cleanroom vibration challenges:

Vibration Analysis — ambient, operational, and diagnostic testing on structures and machinery.

Finite Element Analysis (FEA) — simulation for stiffness, modes, and response.

Modal Analysis & Model Updating — correlate models with test data to validate design changes.

Mechanical Design of Plinths & Support Structures — concept through to manufacture oversight for uniform stiffness plinths.

Engineering Compliance (Noise & Vibration Standards) — demonstrate conformance to manufacturer limits and international criteria.

Further Information

For independent vibration assessments or support with plinth design and compliance, please call us on 01908 643433 or contact us.

Authored and/or Reviewed by the Director, Paul Schmitz MBA CEng MIMechE MIoA — Chartered Mechanical and Acoustic Engineer

Published: • Last updated:

Mechanical Engineering Consultants Ltd (Environmentally Sound) — Registered in England & Wales (Company No. 03619727).

.png)