Mechanical Design Services

"Start with the failure knowledge most teams only gain after test or field problems."

What we do for you

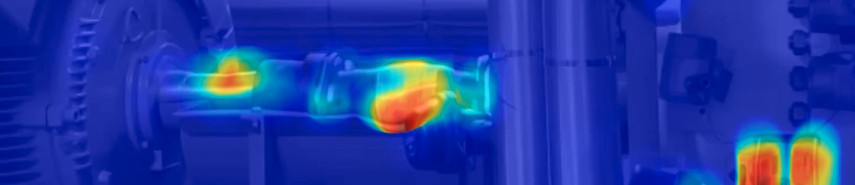

We're mechanical design engineers with extensive experience and expertise in designing and developing products to meet environmental elements and climatic conditions; particularly designs that have vibration and noise challenges.

Who are we and what is your product?

We're an experienced and independent small mechanical engineering consultancy with expertise in vibration and noise.

As mechanical engineers we engineer and design products to customer requirements to be resilient to environmental elements, as typically described in RTCA/DO-160* and MIL-STD-810.

Why does our service matter?

As mechanical engineers steeped in product design, development and testing, our experience is the design input to new products. We know what failures occur in typical testing, and therefore know what to design for and how to design to pass those tests.

Many companies use computer aided design (CAD) software packages, analysis software and more to design products; but few use testing experience as an input to the initial design.

With our testing experience, you can start your design with knowledge that most gain only after they fail testing; this gives you a head start on your competition and a better probability of passing development and qualification testing.

Saving you time. Saving you money. Putting you first to complete the project!

Please read failure investigation for an insightful scenario.

Designing with the advantage: we’ve seen what goes wrong

Most mechanical designs don’t fail on-screen - they fail in service, on the test rig, or during commissioning. A significant proportion of our work starts with products and machines that underperform or fail, and ends with design improvements that are verified by measurement, analysis and repeat testing where appropriate.

This matters because troubleshooting underperformance teaches you what CAD models and ideal assumptions can miss: real boundary conditions, real excitation mechanisms, real variability in assembly and installation, and the small details that drive big reliability and noise outcomes.

Underperforming machines (excess vibration, instability, unacceptable dynamic response)

Vibration-driven fatigue (cracking at brackets, weld details, interfaces, fillets and fastener lines)

Joint problems (loss of preload, loosening, fretting, slip-stick, “working” interfaces)

Qualification surprises (vibration/shock/thermal issues where fixturing and boundary conditions matter)

Noise caused by vibration (structure-borne transmission paths, tonal components, panel radiation)

So when we support your mechanical design, you’re not just buying CAD and analysis - you’re buying design decisions informed by failure modes we’ve already seen, and a verification mindset that gives your project a better probability of passing first time and remaining reliable in service.

What do we have that others don't?

Experience in designing products to pass development and certification testing. Our greatest asset is the combination of test experience and hands-on problem solving when designs underperform.

Areas in which we can assist you:

In-house expertise in vibration, shock, temperature, sand and dust, water, altitude

Test knowledge and experience

Product requirements

Proof of concept

Extensive product testing experience

Troubleshooting and design improvement

Mechanical engineer vs mechanical designer

We are both. And more!

Key facts about us:

We are an independent engineering design firm with passion and tenacity in finding solutions for challenging designs.

With extensive experience in design, proof of concept, product testing and certification for the aerospace and automotive industries.

Hands on experience when correcting the designs of products to meet demanding requirements.

28 years of testing to standards such as MIL-STD-810 and RTCA/DO-160*, plus problem solving through testing and finite element analysis.

Explore our Finite Element Analysis (FEA) page - used extensively to validate and optimise mechanical designs for vibration, fatigue and structure-borne noise.

The design of the perfect product has an iterative process of design and analysis before the subsequent phase of testing. We have extensive experience in all three.

Ruggedised design and exposure to vibration and shock requires expertise in structural dynamics and model updating to achieve design requirements vital to the survival and resilience of products exposed to environmental elements.

Case Study Examples

Falcon SPDB

Structural vibration

Vibration solution

Machine improvements to increase maintenance intervals

Improving designs to take more load

Improving designs to be more resilient to harsh and extreme environments

Fixing failure by design

Design for small spaces: space saving and weight saving

What Are the Different Types of Mechanical Design Services?

Adaptive design

Development design - improving existing designs

New design - creating a unique product

Computer aided design (CAD)

Finite element analysis (FEA)

How much do our mechanical design services cost?

We have competitive rates, and quotations are provided based on estimated time and resources required.

How can I buy your product?

Please give us a call or email us to arrange a meeting to discuss your problem and requirements. This call is free and you'll be surprised what we can do for you.

What are your credentials?

The company is directed by a Chartered Mechanical Engineer and Chartered Acoustical Engineer with over 28 years’ experience across multiple sectors. He has extensive experience and expertise designing mechanical products, and is very approachable.

What you can expect

Following the initial meeting, we work with you to confirm mechanical design requirements before design and analysis commences.

How to contact us?

To find out more about our mechanical design services, telephone or email.

Return to Vibration & Dynamics.

.png)